PET bottle ejection PA series

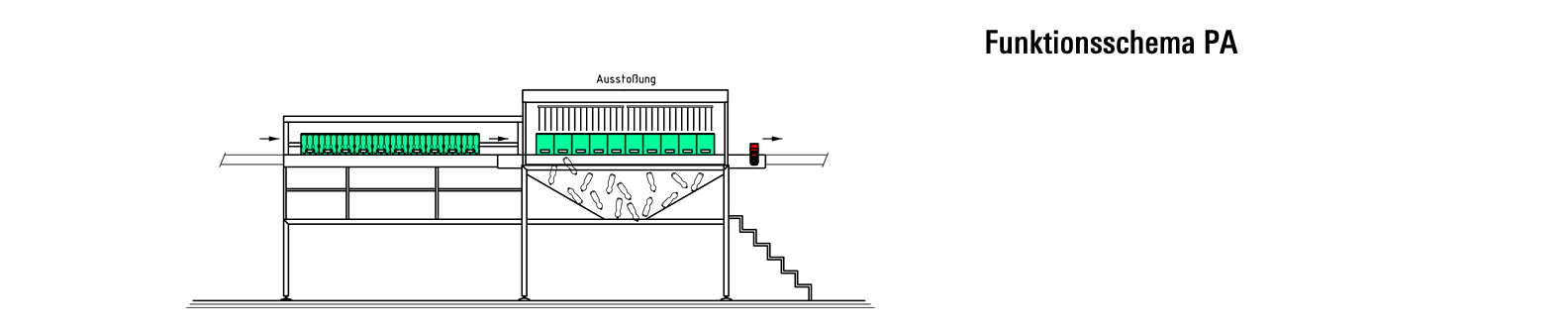

The fully automatic BOHRER PET ejection machine was specially developed for removing any deformed, glued and wedged bottles in the beverage crates before cleaning them in the washing machine.

Any remaining or jammed bottles are reliably detected in an empty compartment detection system and completely removed from the crate by a subsequent pneumatic ejection device.

The unit can be universally adapted to different crate formats and compartment geometries. This PET ejection device is connected to an upstream crate upward turning unit or to a sliding turning unit that moves downwards.

Capacity

from 500 to 5000 crates/h

(other capacities on request)

Area of application

- Mineral springs

- Soft drink manufacturers

Technology

The machine structure, which has been tested for years, is completely made of stainless steel, and is designed for durability and ease of maintenance and cleaning.

Specially embossed hinged slat chains ensure that the crates are carried along safely and at a distance, so that the crates are handled gently when the crates are jammed

Largely dimensioned safety glass windows, as opposite to the black-box crate washers, ensure transparency and easy access to the machine.

For drives and control components, we only use energy-efficient quality products from leading manufacturers. This guarantees a seamless supply of spare parts worldwide and maximum energy use.

* optional