HIGH PERFORMANCE IN CLEANLINESS, EFFICIENCY AND PROFIT-ABILITY

Robust, environmentally friendly and reliable – 365 days around-the-clock operation

Our flexible, robust industrial cleaning systems in a continuous process are all-rounders on the highest technical level. The cleanliness of small load carriers, reusable transport packaging, trays and pallets is the top priority, especially in the automotive industry, for component suppliers and in logistics. Our machine structure complete in a stainless steel hygienic design with the most modern energy-saving drives and the possibility of combining a wide variety of high-end cleaning components, container turning stations, spray water blow-off units and high-pressure drying systems according to container requirements are the outstanding features of the BOHRER cleaning systems.

Crate washers | RH series

Find out moreUniversally equippable module tunnel crate washer for all ranges of capacities. Modern tunnel crate washer in a hygienic design with one cleaning level. It can be combined with a crate drying station.

Area of application

Meat processing industry, large bakeries, fish processing industry, dairies, clinics and hospitals

Pallet washer | PH series

Find out moreSpecial pallet washer. Universally equippable with high-pressure spraying stations, draining stations and high-performance drying stations.

Area of application

Breweries, mineral water and soft drink manufacturers, dairies, food industry, logistic industry

Tunnel washer | R series

Find out moreClassic, universally applicable two-end tunnel washer with one spraying level, without immersion soaking bath. The R series is the economical solution in the small and medium capacity ranges.

Area of application

Breweries, mineral water and soft drink manufacturers, dairies

Combined washer with blow-off station | RG series

Find out moreCombined two-end machine with intensive spraying and retained water blow-off.

Area of application

Foodstuff wholesale, bakeries

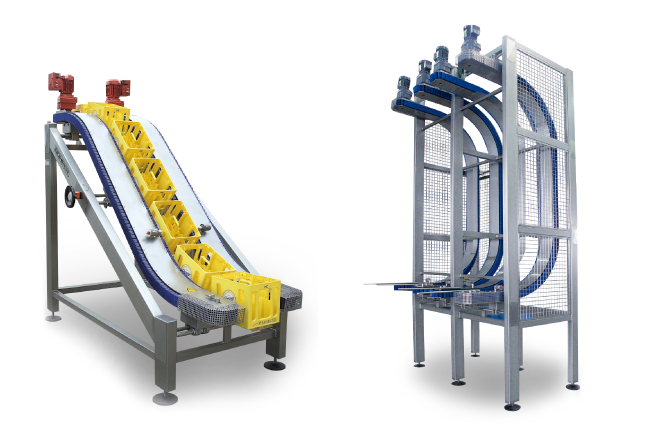

AF upward turning unit | AW turning station

Find out moreSpace-saving option to compensate for height differences.

S-turning station

Find out moreCoarse dirt emptying before the cleaning machine. For effective lye saving and trouble-free operation of the crate washer.

Non-adherent coarse dirt, bottles and broken glass are removed by turning the crate before it enters the crate washer.Area of application

Breweries, mineral water and soft drink manufacturers, dairies, food industry, industry/logistics

Retained water blow-off unit | G series

Find out moreExternal unit for retained water blow-off for all types of crates and containers. High-performance blower with air nozzles that can be adjusted to specific containers

Area of application

Breweries, mineral water and soft drink manufacturers, dairies, industry, clinics and hospitals

BOHRER special solutions

Find out moreRegarding our container cleaning systems, we think without limits, in all service areas and branch solutions.

We safely remove any deformed, glued or wedged PET non-returnable bottles in front of the crate washing machine with maximum performance.